Multipurpose Function Boasting 1- stich functions, the sewing machine PRO has the ability to do almost any stitching or repairing of your fabrics. Selecting your desired stitching is also incredibly easy with just a quick twist of the dial to the corresponding numbers. The sewing machine PRO also comes with a reverse stich function which allows you to further reinforce the beginning and end seams.

Work Light Sewing needs a good eyesight when it comes to precision stitching, therefore the sewing machine PRO provides a work light located just above the sewing needle to help illuminate your sewing. It’s also great when you need that extra light while working with no so favourable light conditions.

Portable Sewing The sewing machine PRO has the ability to go full portable running just on batteries so you can literally start sewing anywhere, anytime. Besides that, the compact and lightweight design makes it so much easier to bring it around and store as well.

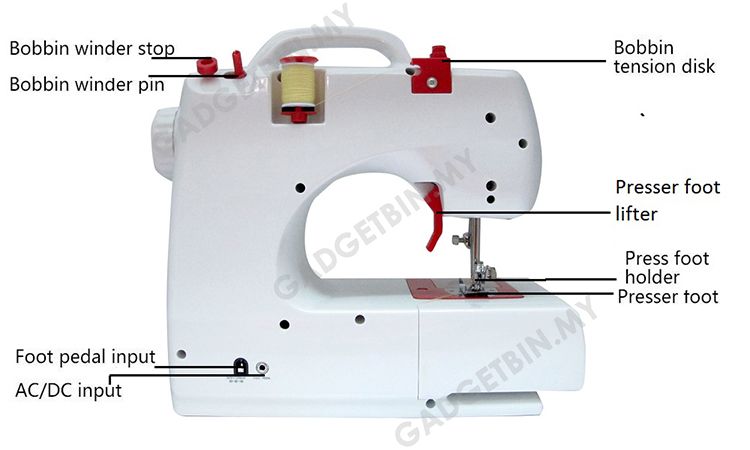

| You can't get proper tension without correct threading. All machines have basically the four tension devices shown here- thread guides, tension discs, tension regulator for upper thread, and bobbin-case spring for bobbin thread- which ensure that the same amount of thread flows simultaneously from the needle and the bobbin, producing a symmetrical stitch. |

Meet your tension tools

In order to form a row of stitches that looks the same on both sides of the fabric, the same amount of thread needs to flow from the spool and the bobbin simultaneously. This is accomplished by running the threads through various tension devices, including the thread guides, tension discs, and tension regulator on the machine head for the upper thread(s), and the bobbin-case spring for the bobbin thread (see "Tension devices and proper threading"-right). Some machines also include a small hole in the bobbin-case finger, through which to feed the bobbin thread to increase the tension for improved stitch definition when topstitching, satin-stitching, and embroidering, without touching your tension settings.

The tension discs and tension regulator together are called the tension assembly. The tension discs squeeze the thread as it passes between them, while the tension regulator controls the amount of pressure on the discs. On older ma- chines there are only two tension discs, controlled by a screw or knob. On newer models there are three discs controlled by a dial or key pad on the front of the machine, which can regulate two threads at once.

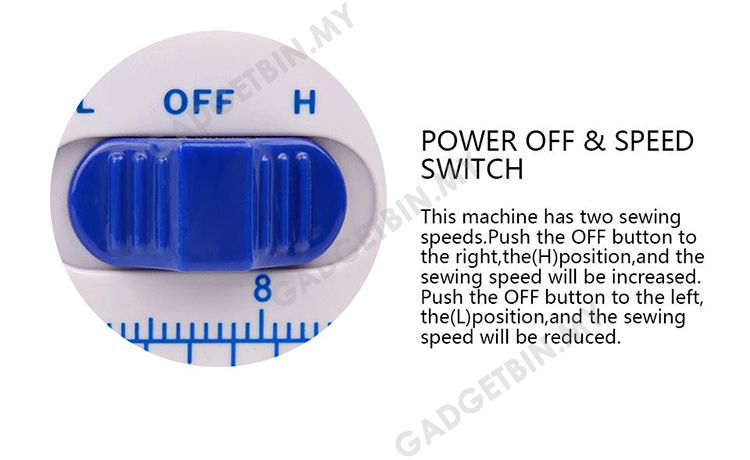

In either case, the tension regulator is elementary: When adjusted to a higher number (turned clockwise), the discs move closer together, increasing the amount of pressure. Turned to a lower number (counterclockwise), the discs move apart, decreasing the pressure. Using a thicker thread without resetting the dial will increase the pressure and cause the upper thread flow to decrease, unless you've got a newer machine that makes automatic upper-tension adjustments. Since the bobbin tension is not self-adjusting, the lower tension may need to be adjusted manually to match.

In addition to guiding the thread along its path, each thread guide exerts a small amount of resistance on the thread, adding to the tension from the discs to achieve balanced tension. Bottom line: Always make sure all guides are threaded before stitching.

The flat bobbin-case spring exerts pressure on the thread as it comes out of the bobbin case. The amount of pressure is regulated by a small screw at the rear of the spring. Both the spring and screw are easy to locate when the machine has a separate bobbin case. When the machine has a drop-in bobbin with a built-in bobbin case, locating the tension screw can be more challenging. Both types are shown in the drawings below. In either case, to increase the resistance, use a small screwdriver to turn the screw clockwise (to a higher number) or counterclockwise (to a lower number). Turn the screw in small increments and never more than a quarter-turn between tests. This helps you keep track of how much you're changing your settings and reduces the risk of losing this very small screw.

Optional Add On

EXPANSION BOARD

SEWING SET

100 PCS SEWING KIT